AQC has the expertise to think along and advise during the design phase of the PCB. We assure you that we will answer all questions quickly, adequately, but above all in a customer-oriented way.

We cherish our Lab & Quality

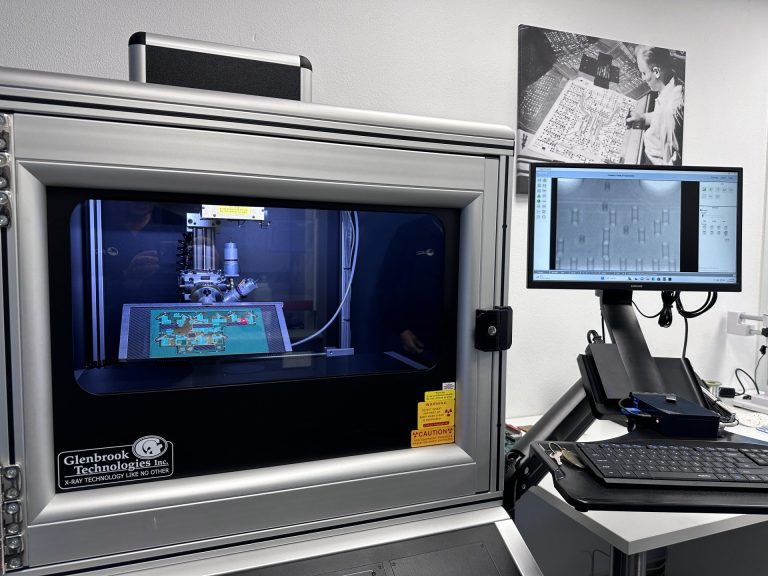

We cherish our independence, especially in quality control. Our in-house laboratory is equipped to double check the quality of delivered products. Did we receive exactly what you asked for, undamaged and ready to use? No product leaves the AQC headquarters without inspection according to AQL method.

QualitiesOur qualities

- Plating thickness (Fisherscope type XDLM232)

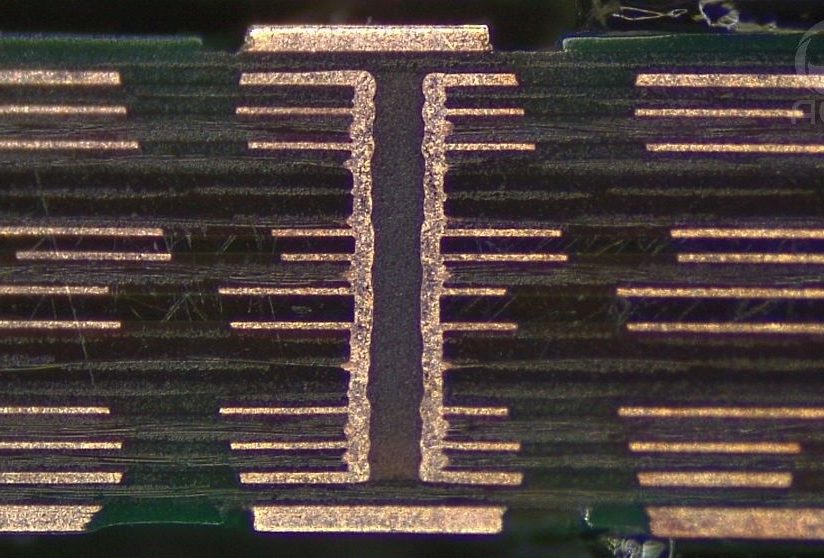

- 100% visual inspection (LEICA S91)

- Thermal stress test

- Laser ans other PCB repairs

- Surface roughness measurements

- Solderability test

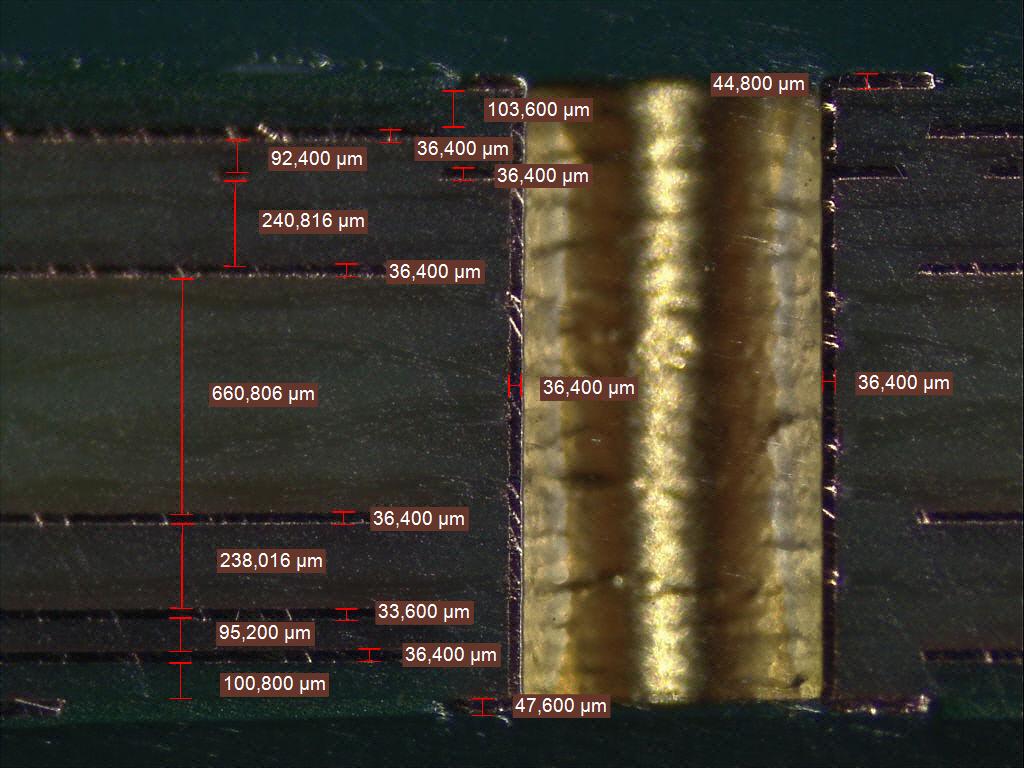

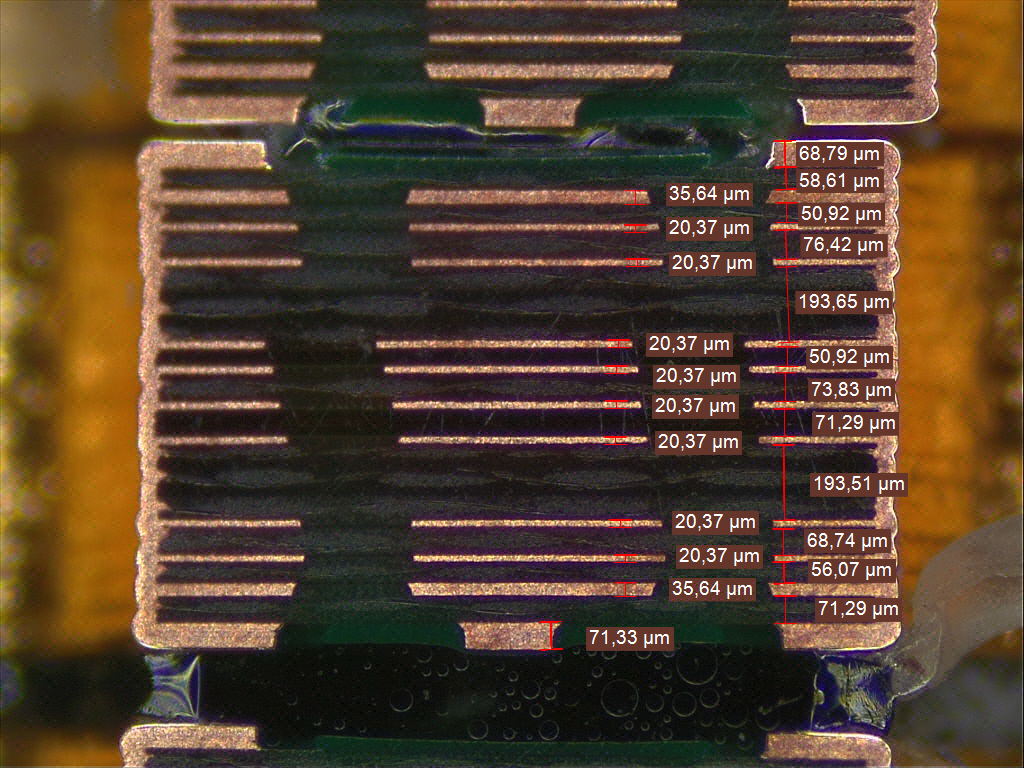

- Microsections and metallographic analysis (LEICA DM 750M)

- Pressfit check (pin gauge set)

ProductsDiscover products

The most ideal manufacturer for each type of product. Quality/delivery time/price/volume/reliability/technology. Please specify what is important for you.

Request a quoteCapabilitiesExplore capabilities

Not only capabilities in products but also in production locations on other continents. This allows AQC to easily switch in case of a calamity.

Explore capabilitiesInterested? Request a quote directly

We provide excellent Advise & support

- Advice throughout the design process

- Verification that the product is manufacturable

- Tips & tricks for your PCB Design Project

AQC quality

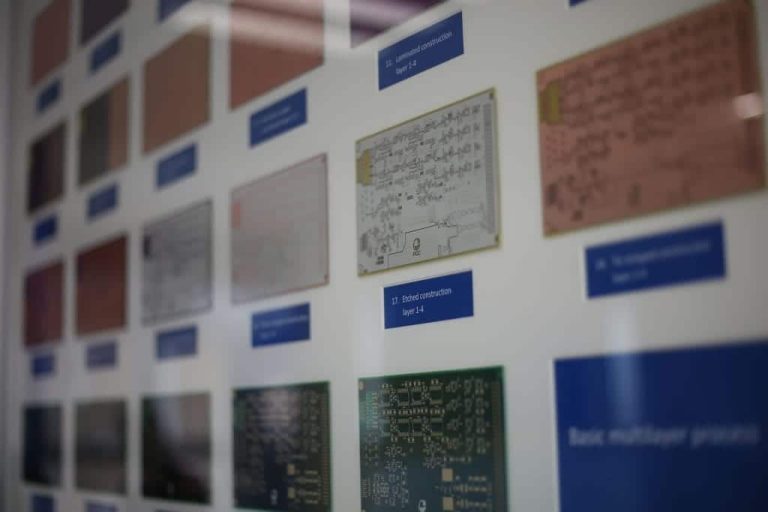

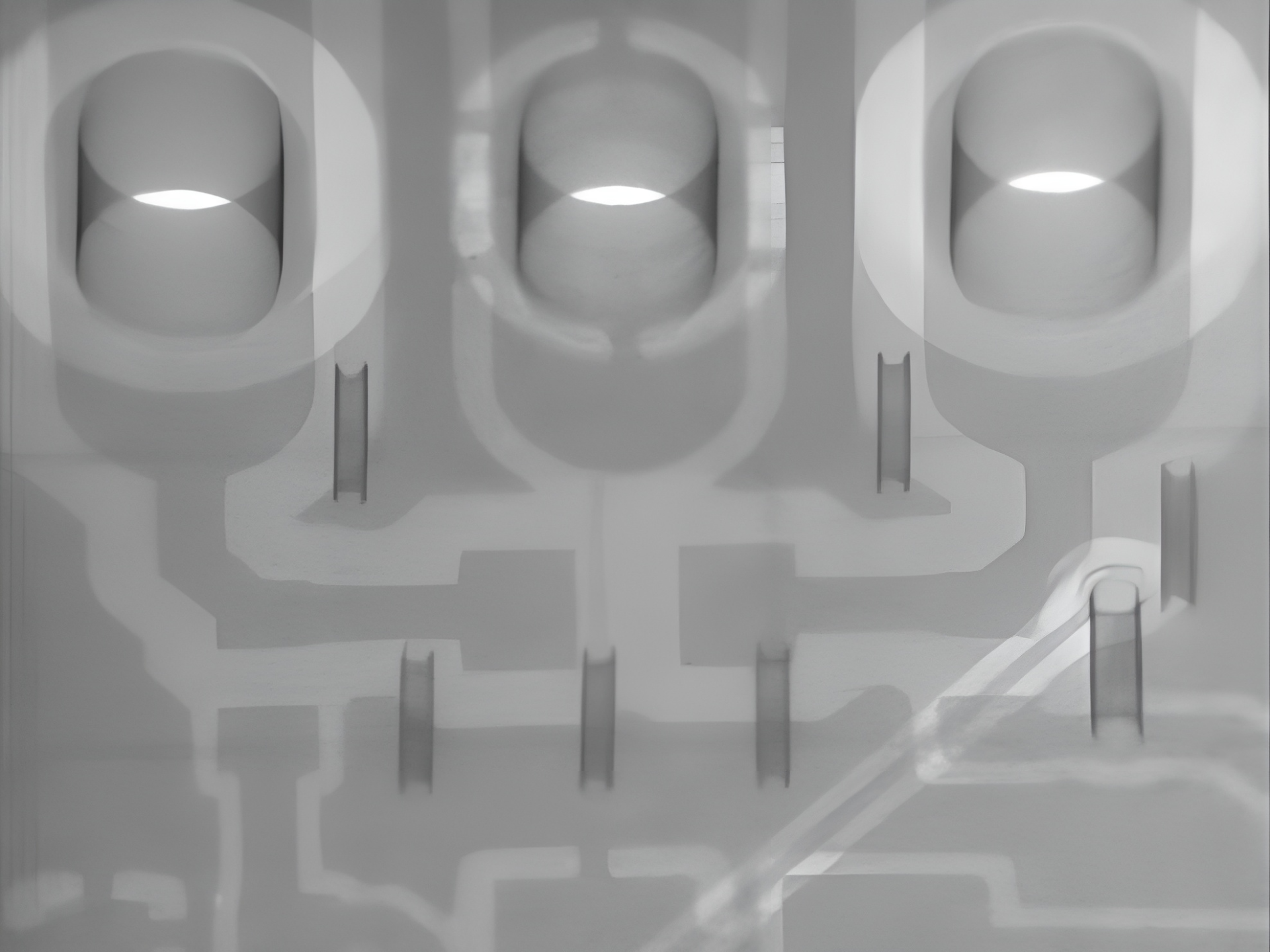

We cherish our independence, especially in quality control. Our in-house laboratory is equipped to double check the quality of delivered products. Did we receive exactly what you asked for, undamaged and ready to use? No product leaves AQC headquarters without inspection according to AQL method. With our Beuhler machine we make microsections to test the metallurgical and mechanical quality of the PCBs. A microsection perfectly shows whether all drill holes are precisely aligned and whether the product meets IPC standards. It is a special service that our customers greatly appreciate.

Our preferred factories also use this service for testing during their R&D process. Before we launch a new prototype, we all want to be 100% sure of faultless and consistent performance. Accurate testing can make all the difference.

Obviously, our plants are monitored daily by our management system. Communication is crucial with established KPIs and objectives which are discussed regularly. In addition, regular audits are conducted to ensure the quality.

Do you have any questions or want to make an appointment?Contact us

- info@aqcbv.com Send us an email

- 088-0045500 Reachable from 08.00 to 17.00 hours